RF Listener

I printed the frame from PLA and that went smoothly. I find that when you design a part specifically for 3D printing you almost always get good results.

I printed the frame from PLA and that went smoothly. I find that when you design a part specifically for 3D printing you almost always get good results.I tried some of those decorative first layer patterns for the covers and they came out quite nice. An additional benefit I discovered is that they seemed to have fewer warping issues than the regular linear fill, I think this is because the lines don't all pull in the same direction as the material shrinks.

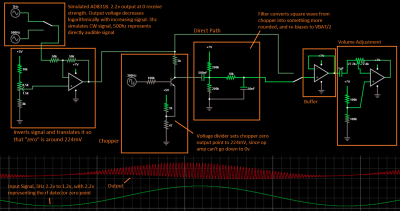

For the electronics, I started by designing the circuit in Falstad Circuit Simulator. I tested out the chopper and tweaked the resistor values until it worked well. As I designed the op-amp part of the circuit, I realized it would not be practical to have 0V = 0 Signal, since the op amps don't function correctly near the rails. Instead I made "zero" 224mV.

For the electronics, I started by designing the circuit in Falstad Circuit Simulator. I tested out the chopper and tweaked the resistor values until it worked well. As I designed the op-amp part of the circuit, I realized it would not be practical to have 0V = 0 Signal, since the op amps don't function correctly near the rails. Instead I made "zero" 224mV.Once I had the circuit working in the sim, I built it breadboard and used a function generator as input. After fixing a couple of minor issues, the two actually agreed pretty well!

Next I duct-taped the breadboard onto the frame and tested it out. This turned out to be really convenient for testing improvements.

Next I duct-taped the breadboard onto the frame and tested it out. This turned out to be really convenient for testing improvements.Using this setup...

I added a peak detector to the amplitude path, which made the quick blips of digital signals much louder.

I added an exponential amplifier before the speaker, to cancel out the log response of AD8318.

Lastly, I moved the gain adjustment to the input side of the circuit instead of the output. This keeps the intermediate amplifiers in a more predictable operating range and also allows the gain adjustment to effect the bar graph as well the audio.

I added a peak detector to the amplitude path, which made the quick blips of digital signals much louder.

I added an exponential amplifier before the speaker, to cancel out the log response of AD8318.

Lastly, I moved the gain adjustment to the input side of the circuit instead of the output. This keeps the intermediate amplifiers in a more predictable operating range and also allows the gain adjustment to effect the bar graph as well the audio.

I was planning to assemble the circuit on one of these protoboards.

I was planning to assemble the circuit on one of these protoboards.Honestly that would have been a more time efficient way to do it, but I much prefer designing PCBs to soldering rats-nest protoboard circuits, so I made a PCB instead.

I laid the circuit out in Diptrace, and ordered it from Aisler. 23USD and a few weeks waiting for the deathly slow USPS later, I had PCBs in hand.

I laid the circuit out in Diptrace, and ordered it from Aisler. 23USD and a few weeks waiting for the deathly slow USPS later, I had PCBs in hand.I assembled the board manually with tweezers and a soldering iron. If you have a stereo microscope soldering 0603 parts by hand is pretty easy. I didn't take any pictures of that process unfortunately.

The assembled board didn't work right away. Unfortunate, but I guess that's what I get for skipping my pre-order checklist. It turned out that a few of the wires in my schematic were on top of each other but not actually connected. Doh.